Tusuka is committed to ensure sustainable business practices. Sustainability is profoundly implanted into the business. The company production philosophy is based on asceticism to minimize the usages of raw materials, energy, water and chemicals.

Effluent Treatment Plant (ETP)

TUSUKA ETP is Graded GREEN by BluWin Limited through H&M

Tusuka has implemented a Central Effluent Treatment Plant (biological) having capacity 300m3/hr or 7,200m3/day. The driving of the whole system is controlled by an automated electric panel equipped with PLC + VFD with alarm devices for immediate checking of the possible damages as well as Supervisory Control and Data Acquisition (SCADA) monitoring system.

The efficiency of BIOLOGICAL ETP is very satisfactory, not only for the quality of the output water (DoE, BSR & ZDHC compliance value), but also for an economically & ecologically sustainable due to less operation & maintenance cost, low labor cost, less sludge treatment and disposal cost.

Tusuka always ensuring that our wastewater discharge do not adverse effect to the environment.

Tusuka Biological ETP has contracted & commission with a highly qualified professional engineering body (JOSEPH EGLI ITALIA, s.r.l).

Presently, Tusuka is on the way of 3R (Reduce, Reuse, Recycle) strategy. Furthermore, we have a plan to implement Zero Liquid Discharge (ZLD) Technology with thinking our environmental responsibility and also global perception to make sustainable environment.

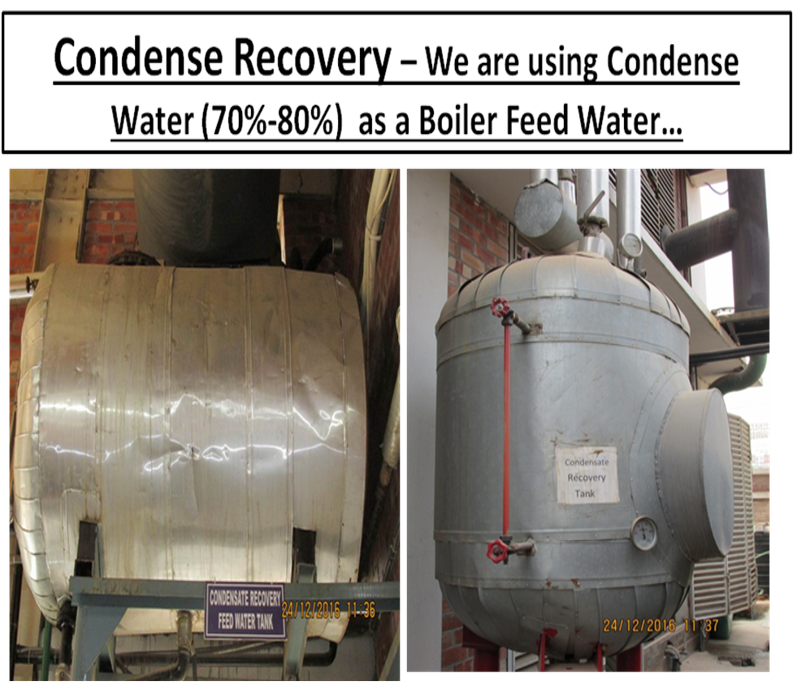

Condensate (Hot water) Recovery

Condensate water recovery means providing a second pipe to route & the Condensate (hot water/steam mixture) from the point of use or process back to the central boiler. Recovering condensate helps in many ways. Following are a few benefits of recovering condensate and mixing it with makeup water in a feed water tank.

·Condensate is an excellent source of feed water as it is relatively pure (compared to most water supplies) being condensed water vapor.

·Boiler water cycles of concentration can be increased and blow down amounts can be reduced with its use

·Improves energy efficiency

·Reduced greenhouse gas emissions (10% and more)

·Reduces water treatment chemical cost

·Reduces make-up water costs

·Reduces load on sewer system (Effluent Treatment Plant) and disposal costs

·Meet environmental regulations

·Condensate can also be used as the hot process water to use the enthalpy for heating coils or heat exchange units

Energy efficieny

-Tusuka uses LED bulbs in place of incandescent bulbs like T-12 or T-8 and uses servo motor & VFD control motor, e-flow chemical spray machine, green dryer, energy efficient washing machine,VFD controlled air compressor, IE3 motor & has all exhaust fan replaced by energy efficient motor.

– Tusuka has also implemented a solar power generation unit as a pilot project to conserve natural resources.

Leakage and consumption monitoring

– A small leak of 1 mm at 10 bar results in a loss of approximately 2.5 kg of steam per hour. Tusuka monitoring team relentlessly works to identify and rectify the steam leakages.

Solid waste management

– As part of agreement with EVA Enterprise & Ria Drum House, Tusuka sent them 910 tons/year of

solid cutting & others waste for recycling.